BLAZING SPEED

With speeds of up to 4,364 A4 pages per minute, PROSPER Presses easily achieve an average monthly print volume (AMPV) of up to 90 million pages – whether printing on ground wood, matte, silk or glossy paper.

IMAGE DETAIL

The PROSPER Press achieves up to 200 LPI with drop placement accuracy that exceeds other inkjet technologies. And it maintains its high-quality, accurate color over long runs, thanks to in-system monitoring.

UNRIVALED QUALITY

PROSPER 6000 produces vibrant photorealistic images day after day, which are comparable to offset quality and durable enough to withstand frequent handling. Quality that's impressive enough to please the most demanding client.

DRAMATICALLY REDUCED SETUP AND MAKE-READY

The significant front-end document processing capabilities of digital printing, as well as built-in press design and recallable job setting features, are also yours with PROSPER Presses. Powerful digital front ends shorten time-intensive prepress operations by reducing workflow steps and traditional on-press activities, such as job setup and make-ready time.

A CHOICE OF WEB PATHS

The flexibility of multiple paper paths (depending on ink coverage and drying needs) minimizes press downtime by reducing potential substrate issues. Combined with its variable-speed capability, this greatly reduces paper waste – both during press setup and press stops.

COMPELLING ECONOMICS

PROSPER Presses can deliver significant savings by optimizing consumption of ink and fluids compared to thermal inkjet devices. Even better, you can improve your bottom line with savings on press operations— including parts and service—that are up to 20% lower than thermal inkjet presses.

MORE SUBSTRATE OPTIONS

A broad range of commercially available inkjet-compatible substrates can be run on PROSPER Presses at full press speeds. These include industry standard uncoated, coated, and even glossy papers from 42-270 gsm (12 point) on roll widths from 8 to 25.5 inches (20.3–64.8 cm). With the optional heavy substrate feature the PROSPER 6000S simplex press can print carton board up to 405 gsm (24 point) thickness.

CLEAN OPERATION

KODAK PROSPER Press Inks contain minimal VOCs (Volatile Organic Compounds). They're also toy safe—making them a safe solution for children’s and juvenile books—and food safe, for indirect contact in packaging applications. No need for a hazardous waste removal process, either.

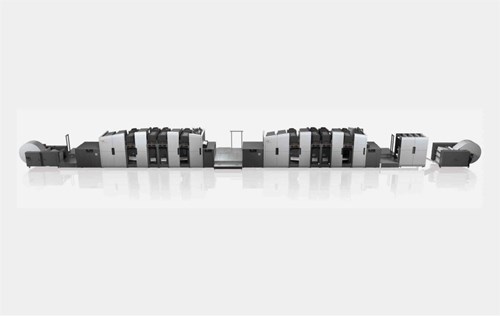

KODAK PROSPER 6000C & 6000P Press Technical Specifications

Throughput

Up to 1,000 fpm (300 mpm), up to 4,364 A4 ppm, 8-, 12-, 16-page signatures 1

Image quality

Approaching 200 lpi at 650 fpm (200 mpm); 133 lpi at 1,000 fpm (300 mpm)

Substrates

Types: Uncoated free sheet groundwood and matte, glossy and silk coated papers

6000C: 42 - 270 gsm, 3 - 12 pt, 28# newsprint – 100# cover

6000P: 42 - 125 gsm, 3 - 6.2 pt, 28# newsprint - 80# book weight Roll width: 8 - 25.5 inches (20.3 – 64.8 cm)

Imaging system

Technology: KODAK Stream Inkjet Technology

Ink type: Kodak's aqueous pigmented process color inks

Jetting Modules: 4.16", 48 Jetting Modules within a standard perfecting press

Imaging width: Up to 24.45 (62.1 cm)

Variable cutoff: Up to 54" (137.2 cm)

Duty cycle: 90M A4 or letter pages/month2

File formats

PDF, PDF-VT, PPML/GA, PPML/VDX, VPS, PostScript, AFP

Digital front end

KODAK 700 Print Manager (Version 4.0 or higher is required) contains:

- KODAK 700 Digital Front End contained in two cabinets with 1 Control Server and 8 Print Process Servers

- Each server contains (at a minimum): Dual Quad Core Intel Xeon 2.33 GHz Processors, 6GB RAM, RAID

- with 1TB system storage, and 2TB for image processing, Microsoft Windows 2003 server OS

- Hardware-accelerated image processing technology

- Scalable architecture, for expansion and customer-specific solutions

- Connectivity: Ethernet TCP/IP 1Gbps twisted pair, IPDS (TCP/IP), or JDF/JMF

- One cabinet containing the Kodak Prosper 720 Press Controller

- Speed: Simultaneous RIP and print capability at up to 1,000 fpm (300 mpm) 3

- JDF/JMF: Job ticket control, enterprise connectivity and workflow automation

- Workflow: Open architecture allows integration into a wide variety of workflows, including Kodak Unified

Workflow Solutions. CIP4 JDF compliant, Remote Client, Remote Job Ticketing, Hot folder file submission - IPDS connectivity

Dimensions (L x W x H)

6000C:

Standard configuration: 92 x 26 x 7 feet (28 x 7.9 x 2.1 m)4

L-shaped: 52 x 64 x 7 feet (15.8 x 19.5 x 2.1 m)4

U-shaped: 50 x 43 x 7 feet (15.2 x 13.1 x 2.1 m)4

6000P:

Standard configuration: 78 x 26 x 7 feet (23.8 x 7.9 x 2.1 m)4

L-shaped configuration: 50 x 56 x 7 (15.2 x 17.1 x 2.1 m)4

U-shaped configuration: 42 x 43 x 7 (12.8 x 13.1 x 2.1 m)4

Operating environment

60° to 85°F (16° to 30°C) @ 10 to 90% RH non-condensing; 85° to 104°F (30° to 40°C) @ 10 to 60% RH noncondensing; Altitude above sea level: 6,000 feet (1,830 meters) max.

Power

Electrical voltage: 3-Phase 50-60Hz and 208-230 50-60h

6000C: Consumption during operation at 650 fpm (200 mpm): 34.2 Kw (idle), 377.8 Kw (uncoated papers), 401.9 Kw (glossy and matte coated papers)6

Consumption during operation at 1,000 fpm (300 mpm): 34.2 Kw (idle), 402.8 Kw (uncoated papers), 442.6 Kw (matte coated papers)6

6000P: Consumption during operation at 325 fpm (100 mpm): 187.6 Kw (glossy coated papers)6

Consumption during operation at 650 fpm (200 mpm): 33.6 Kw (idle), 283.2 Kw (uncoated papers), 304.7 Kw (glossy and matte coated papers)6

Consumption during operation at 1,000 fpm (300 mpm): 33.6 Kw (idle), 295.9 Kw (uncoated papers), 341.0 Kw (matte coated papers)6

Consumables

Jetting modules: KODAK PROSPER Press Jetting Modules Inks: KODAK PROSPER Press Pigment Cyan, Magenta, Yellow and Black Inks Other fluids: KODAK PROSPER Press Storage Solution and Replenisher Fluid Ink supply: 208-liter drums (55 gal.)

Solutions

Job submission: KODAK INSITE Prepress Portal System Creation and organization: KODAK INSITE Creative Workflow System and KODAK INSITE Asset Library Production management: KODAK PRINERGY Workflow v5.1 or higher Proofing: KODAK MATCHPRINT Inkjet Proofing System and KODAK MATCHPRINT Virtual Technology Asset management: KODAK Data Management Solutions Color management: KODAK COLORFLOW Software Qualified book finishing solutions: Available from Kodak authorized providers Optional: Auto-splicing and re-winder solutions available from Kodak authorized providers

Optional accessories

KODAK Color Toolkit Plus station

KODAK Color Toolkit - All-inclusive bundle

KODAK PROSPER Press Jetting Module Recovery Station

Auto Splicer (provided by Kodak partner)

Kodak's Ink Estimator Software

1 Based on 24/7 operation at 70% uptime.

2 Includes unwinder, optional rewinder and ink depot.

3 Running power estimates at 25 – 30% CMYK ink coverage.

4 Actual speed and throughput may vary with a specific type of paper and quality expectation;

5 Actual RIP speeds may vary based on complexity of jobs and compliance level of composition engines.

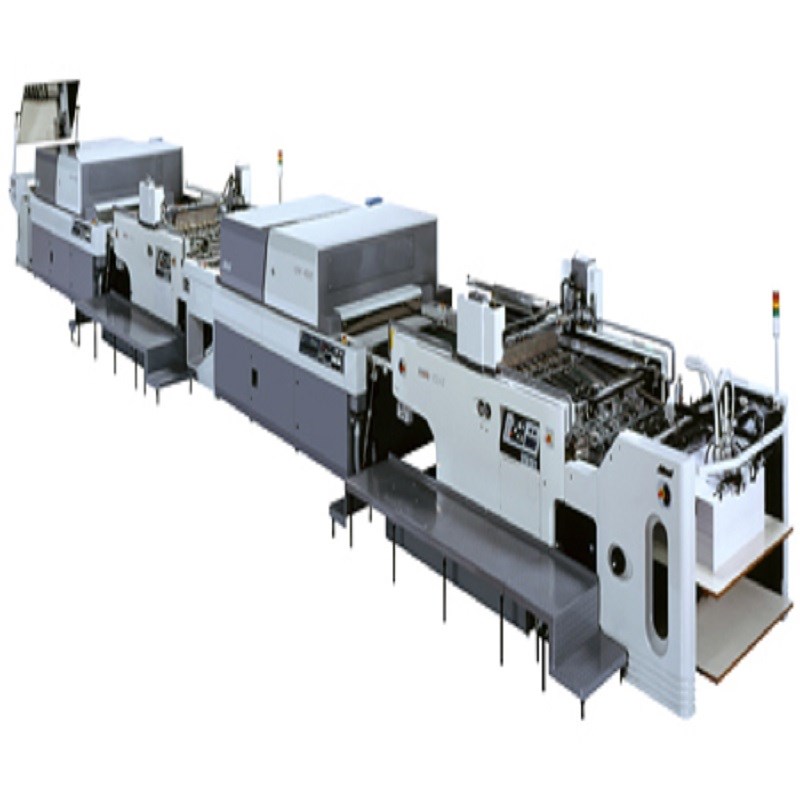

KODAK PROSPER 6000S Press – Standalone and Hybrid

General specifications

Standard configuration

Heavy Substrate Option

Throughput

Up to 1,000 fpm (300 mpm), up to 2,182 A4 ppm,

8-, 12-, 16-page signatures 1

Up to 650 fpm (200 mpm), up to 1,455 A4 ppm,

8-, 12-, 16-page signatures 1

Imaging quality

Approaching 200 lpi at 650 fpm (200 mpm); 133 lpi at 1,000 fpm (300 mpm)

Substrates

Uncoated free sheet groundwood and matte, glossy and silk coated papers 42 - 270 gsm, 3 - 12 pt, 28# newsprint – 100# cover.

Roll width: 8 - 25.5 inches (20.3 – 64.8 cm)

Uncoated and coated paperboard (including but not limited to SBS, CUK, CRB) up to 405 gsm, 15 - 24 pt

Roll width: 8 - 25.5 inches (20.3 - 64.8 cm)

Recommend min. of 118gsm. Wrinkling may occur at lower weights

Imaging system

Technology: KODAK Stream Inkjet Technology

Ink type: Kodak’s aqueous pigmented process color inks

Jetting modules: 4.16”, 24 Jetting Modules within a simplex press

Imaging width: Up to 24.48” (62.17 cm)

Variable cutoff: Up to 54” (137.2 cm)

Duty cycle: 45M A4 or letter pages/month 2

File formats

PDF, PDF-VT, PPML/GA, PPML/VDX, VPS, POSTSCRIPT, AFP

Digital front end

KODAK 700 Print Manager (Version 4.0 or higher is required) contains:

- KODAK 700 Digital Front End contained in two cabinets with 1 Control Server and 4 Print Process Servers

- Each server contains (at a minimum): Dual QUAD CORE INTEL XEON 2.33 GHz Processors, 6GB RAM,

RAID with 1TB system storage, and 2TB for image processing, MICROSOFT WINDOWS 2008 server OS - Hardware-accelerated image processing technology

- Scaleable architecture, for expansion and customer-specific solutions

- Connectivity: Ethernet TCP/IP 1Gbps twisted pair, IPDS (TCP/IP), or JDF/JMF

- One cabinet containing the KODAK PROSPER 720 Press Controller

- Speed: Simultaneous RIP and print capability at up to 1,000 fpm (300 mpm) 3

- JDF/JMF: Job ticket control, enterprise connectivity and workflow automation

- Workflow: Open architecture allows integration into a wide variety of workflows, including KODAK Unified

Workflow Solutions. CIP4 JDF compliant, Remote Client, Remote Job Ticketing, Hot folder file submission - IPDS connectivity

Dimensions (L x W x H)

Standard configuration: 56 x 21 x 8 feet (17 x 6 x 2 m)4

Physical dimensions of press: 33 x 21 x 8 feet (10 x 6 x 2 m)5

Operating environment

60° to 85°F (16° to 30°C) @ 10 to 90% RH non-condensing; 85° to 104°F (30° to 40°C) @ 10 to 60% RH noncondensing; Altitude above sea level: 6,000 feet (1,830 meters) max.

Power

Electrical voltage: 3-Phase 50-60Hz and 208-230 50-60h

Consumption during operation at 650 fpm (200 mpm): 17.1 Kw (idle), 188.9 Kw (uncoated papers), 201 Kw (glossy and matte coated papers) 6

Consumption during operation at 1,000 fpm (300 mpm): 17.1 Kw (idle), 201.4 Kw (uncoated papers), 221.3 Kw (matte coated papers)6

Electrical voltage: 3-Phase 50-60Hz and 208-230 50-60h

Consumption during operation at 650 fpm (200 mpm): 17.1 Kw (idle), 201.4 Kw (uncoated papers), 221.3 Kw (glossy and matte coated papers)6

Consumables

Jetting modules: KODAK PROSPER Press Jetting Modules

Inks: KODAK PROSPER Press Pigment Cyan, Magenta, Yellow and Black Inks; Indirect food contact Inks

Other fluids: KODAK PROSPER Press Storage Solution and Replenisher Fluid

Ink supply: 208-liter drums (55 gal.)

Solutions

Job submission: KODAK INSITE Prepress Portal System

Creation and organization: KODAK INSITE Creative Workflow System and KODAK INSITE Asset Library

Production management: KODAK PRINERGY Workflow v5.1 or higher

Proofing: KODAK MATCHPRINT Inkjet Proofing System and KODAK MATCHPRINT Virtual Technology

Asset management: KODAK Data Management Solutions

Color management: KODAK COLORFLOW Software

Qualified finishing solutions: Available from Kodak authorized providers

Optional accessories

KODAK PROSPER IOS Offline Coating Solution; KODAK Color Toolkit Plus Station and training;7

Kodak’s Ink Estimator Software

1 Actual speed and throughput may vary with a specific type of paper and quality expectation; glossy coated papers run up to 650 fpm (200 mpm) only.

2 Based on 24/7 operation at 70% uptime.

3 Actual RIP speeds may vary based on complexity of jobs and compliance level of composition engines.

4 Includes unwinder, optional rewinder and ink depot.

5 Excludes unwinder, festoon and rewinder.

6 Running power estimates at 25 – 30% CMYK ink coverage.

7 A KODAK Color Toolkit Plus Station is mandatory for installations where there is not already a Color Toolkit.