HIGH SPEED PROVIDES UNMATCHED PRODUCTIVITY

500 feet per minute print speed in highest quality mode provides 2,148 pages per minute, 2x to 3x faster than the competition. Reduce labor costs and improve customer satisfaction without compromising quality.

HIGH QUALITY THAT RIVALS OFFSET

Print quality that rivals 200 LPI offset with drop placement accuracy that exceeds other inkjet technologies. Patented KODAK Intelligent Print System constantly monitors and optimizes stitching, color-to-color and front-to-back registration.

HIGH RUN LENGTH = HIGHER PROFITS

Achieve higher run-length cross-over with offset thanks to Kodak’s industry-leading low-cost ink. Drive more profit by growing higher value digital jobs.

EXCEPTIONAL EFFICIENCY

Next generation KODAK 900 Print Manager digital front end with state-of-the art ADOBE APPE 5 RIP and recallable job settings shortens time-intensive prepress operations. An optimized interface with KODAK PRINERGY Workflow maximizes production efficiency and data security.

HUMAN-FRIENDLY INKS

Kodak’s eco-friendly, water-based nanoparticulate pigment CMYK inks contain minimal Volatile Organic Compounds and do not require a hazardous waste removal process. They’re also toy safe for children’s books and food safe for indirect contact in packaging applications.

WIDE-RANGING PAPER CHOICES

Print on inkjet-compatible substrates at full press speeds. These include industry standard uncoated, coated, and even glossy papers from 45-250 gsm on roll widths from 8 to 21 inches (203–533 mm). Standard offset papers can be run with an optional inline pre-coater from one of the numerous vendors now offering them.

SPACE SAVING

Compact and robust press design requires less space than some rival systems. KODAK ULTRASTREAM Technology imaging stations need only 5 print heads per color to print the 520 mm (20.5 in.) width.

|

Press models |

ULTRA C520 for high ink coverage applications ULTRA P520 for medium-to-low ink coverage applications |

|

Print technology |

KODAK ULTRASTREAM continuous inkjet technology |

|

Ink |

KODAK nanoparticulate aqueous pigment CMYK inks |

|

Maximum print width |

520 mm (20.5 in.) |

|

Resolution |

600 x 1800 dpi (200 lpi equivalent) |

|

Speed |

150 meters per minute (500 feet per minute):

|

|

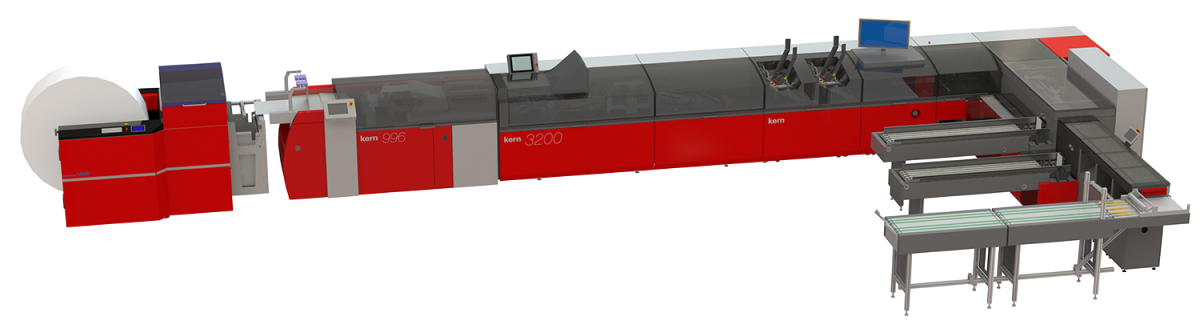

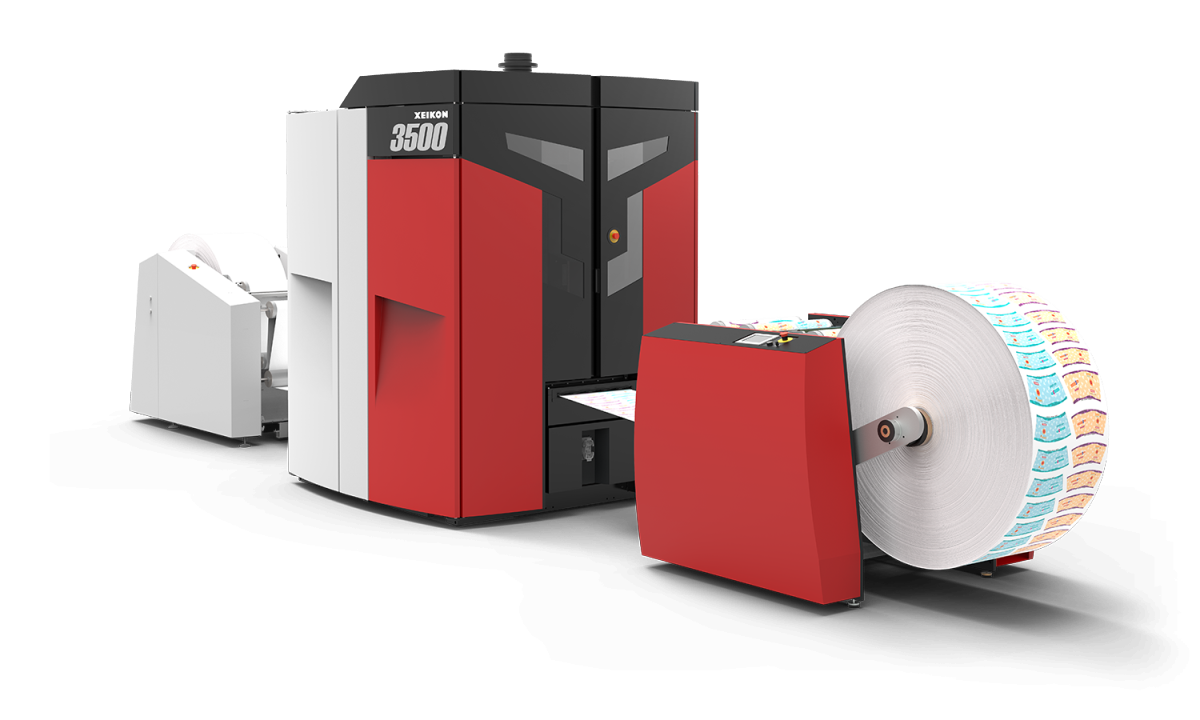

Pre & post press options |

Open architecture tight web paper transport for easy integration with 3rd party equipment:

|

|

Paper widths |

533 mm (21 in.) to 203 mm (8 in) |

|

Paper weight range |

45 – 270 gsm on ULTRA C520 45 – 160 gsm on ULTRA P520 (may print heavier weight papers at reduced speed) |

|

Paper types |

Coated, uncoated and newsprint. Inkjet treated or standard offset with optional KODAK IOS ULTRA P520 may print coated papers at a reduced print speed |

|

Drying |

Intelligent near infrared drying: 2 units in ULTRA P520 and 4 units in ULTRA C520 |

|

Data & press controller |

KODAK 900 Print Manager |

|

Data file formats |

PDF, PDF/VT, AFP |

|

Data inspection system |

KODAK Intelligent Print System for stitching, color-to-color and front-to-back registration Optional image inspection system |

|

Screening |

KODAK Hardware enabled. Choice of KODAK Error Diffusion or Threshold Matrix |

|

Environmental operating ranges |

16 C – 30 C (60 F – 86 F) temperature at 10% - 90% relative humidity 30 C – 35 C (85 F – 95 F) temperature at 10% - 60% relative humidity Altitude: up to 1,830 meters (6,000 feet) above sea level |

|

Power source |

Transport & inkjet 400V, 3 phase; Dryer & unwinder 400V – 480V, 3 phase |

|

Installation floor space |

14.94 meters (48 ft. 10 in.) x 7.31 meters (24 ft.) Includes press, unwind, rewind, DFE, fluid systems, ink tanks, and optional pre or post coater* *Customers choice of pre and post finishing equipment may impact installation space required |

|

Duty cycle |

Up to 60M pages per month |

|

*Specifications subject to change |

|