Paper cup production inspiration

1. Paper cup ideas

Traditionally, beverage cups are manufactured on single- or double-sided PE coated paper. After printing and varnishing, the rolls are either converted into single cups or rolled single cups. This is driven by the type of cup maker being used (paper feed or roll feed). Single-sided coated paper is used for hot drinks and double-sided coated for cold drinks (after serving, condensation may arise on the outer surface affecting the structural strength of the cup in the absence of a layer). outer coating). The PE layers allow the cup to be formed and fixed to the required shape. Usually, they are mainly printed by flexographic printing machines.

Kotkamills has created a plastic-free material for cups, ISLA® Duo cupstock. This easily recyclable and plastic-free cup is based on a water-based dispersion barrier. Barrier, prevent liquid from seeping into paper or leaking, and it adopts direct coating technology. Plastic-free, ISLA® Duo can be recycled with ordinary paper and paperboard waste. In this way, recycling is made as easy as possible, giving both consumers and retailers easy access to promote yarn reuse for other fiber products.

2. Production details

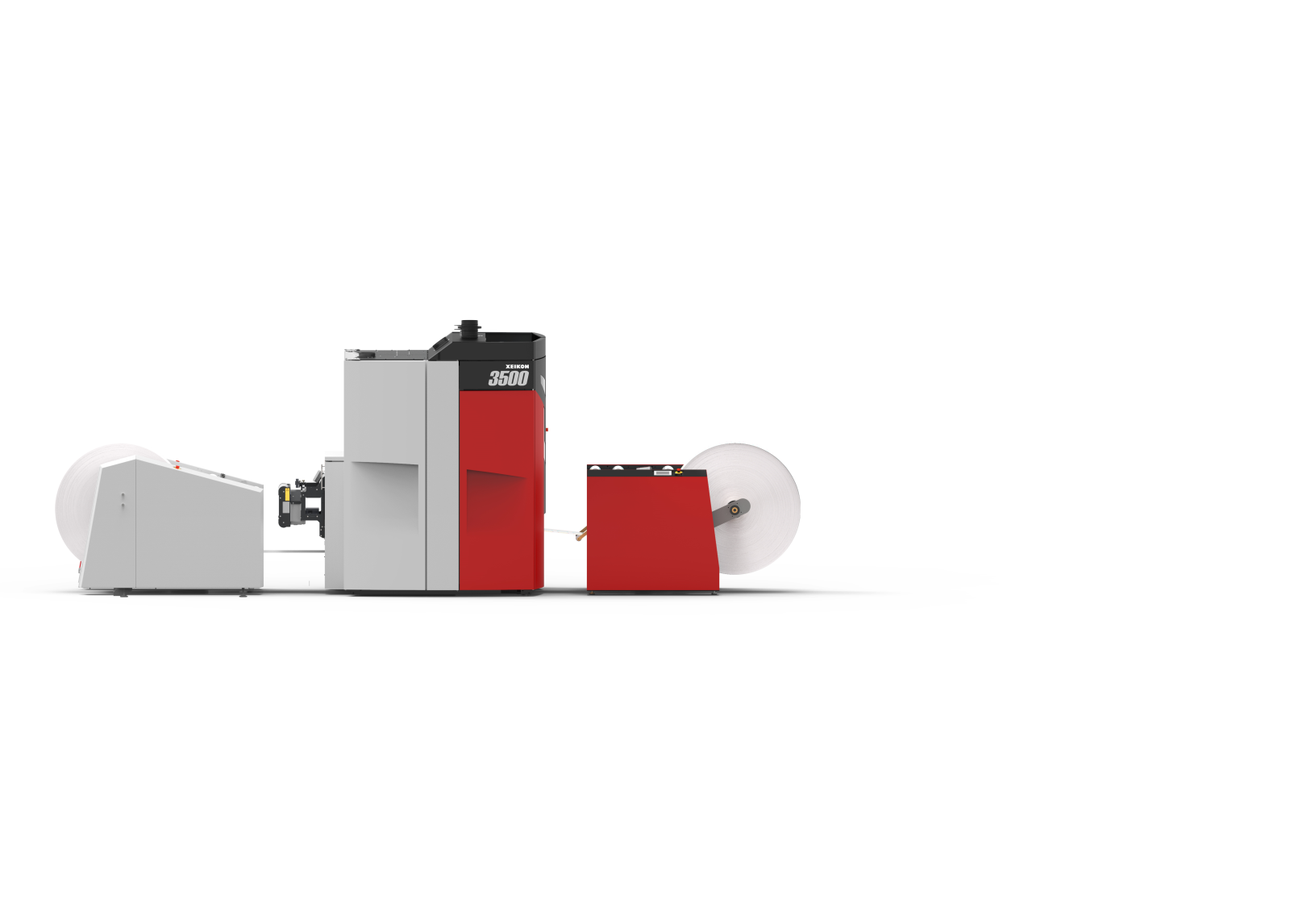

Here you can see a sample drink cup printed on the Xeikon 3500 digital press .

- Print size: 240 x 110 mm

- Substrate: Standard paper substrate with or without PE coating, no primer required

- Ink: Food-safe CMYK ink

- Finishing : Roll-to-roll printing, no additional varnish needed

The Xeikon 3500 has been chosen by manufacturers due to its outstanding print quality and print width of 508mm. Furthermore, the ability to print multiple versions without changing costs and last but not least, food safety compliance technology.

.jpg)

3. The value of digital printing

We recognize trends and want to improve foodservice packaging - creating a better image for consumers. Customers and brands looking for new experiences are driving customizable manufacturing in the short term.

Furthermore, digital printing with Xeikon offers:

- Flexible in running length as it can vary from 1 to many

- Fast and efficient production process, especially when there are many different designs of the same size, which can be merged into a larger print

- Food safety and migration compliance technology

- Excellent de-sticking ability to assist and ensure optimized recycling

4. Which digital press is preferred for paper cups?

Machines for digital printing Xeikon 3500 . The industry leader in digital dry ink printing, producing at 1200 dpi for formats up to amazing speed B2 while providing the full flexibility of the digital front end:

- Dry ink technology: ensuring full compliance with this challenging application from a food perspective

- Wide substrate range: coated and uncoated paper 40 to 350 gsm (27 lb. text to 122 lb. cover)

- B2 format or later: 516 x 730 mm (20.3" x 28.7") or 516 x 1000 mm (20.3" x 39.4")

- High-quality printing: 1200 dpi with wide color gamut and spot color

- Specialized food-safe toner: makes it easy to print on barrier-free materials and PE diaphragms

5. What digital production solutions are offered?

You can see an example of a full production process for a large roll transmission paper cup including:

- Print Medium Unwinder

- Xeikon digital press 35000

- Print Medium Rewinder

Make sure to deliver the roll to the mold further offline - the trimming process. This is a complete digital solution, which comes with all the necessary components for seamless digitally printed packaging.

- Shared: