Printed labels on bags - creativity is endless

1. What is a carrying bag?

The carrying bag is essentially a multi-layer bag (plastic film, aluminum foil and other materials). Marketers see a lot of value in this type of packaging for reasons such as presentation and functionality of the product to the consumer but also sustainability: a bag of proportions is called “ product per pack” is 35:1 which basically means it can carry 35 times its own weight, resulting in less energy consumption to manufacture and transport. This is why so many brands are switching from rigid packaging to more flexible versions. Bags can come in a variety of shapes depending on the size needed, the end-use application, and the function. They are very complicated to manufacture because the bag is a multi-layered product. Vertical bags are often referred to as "bottom gusset" bags. They can stand after being filled with a certain product. They are the perfect solution for applications that use “light weight” and by “standing up” they have a presence almost everywhere.

.jpg)

2. Production details

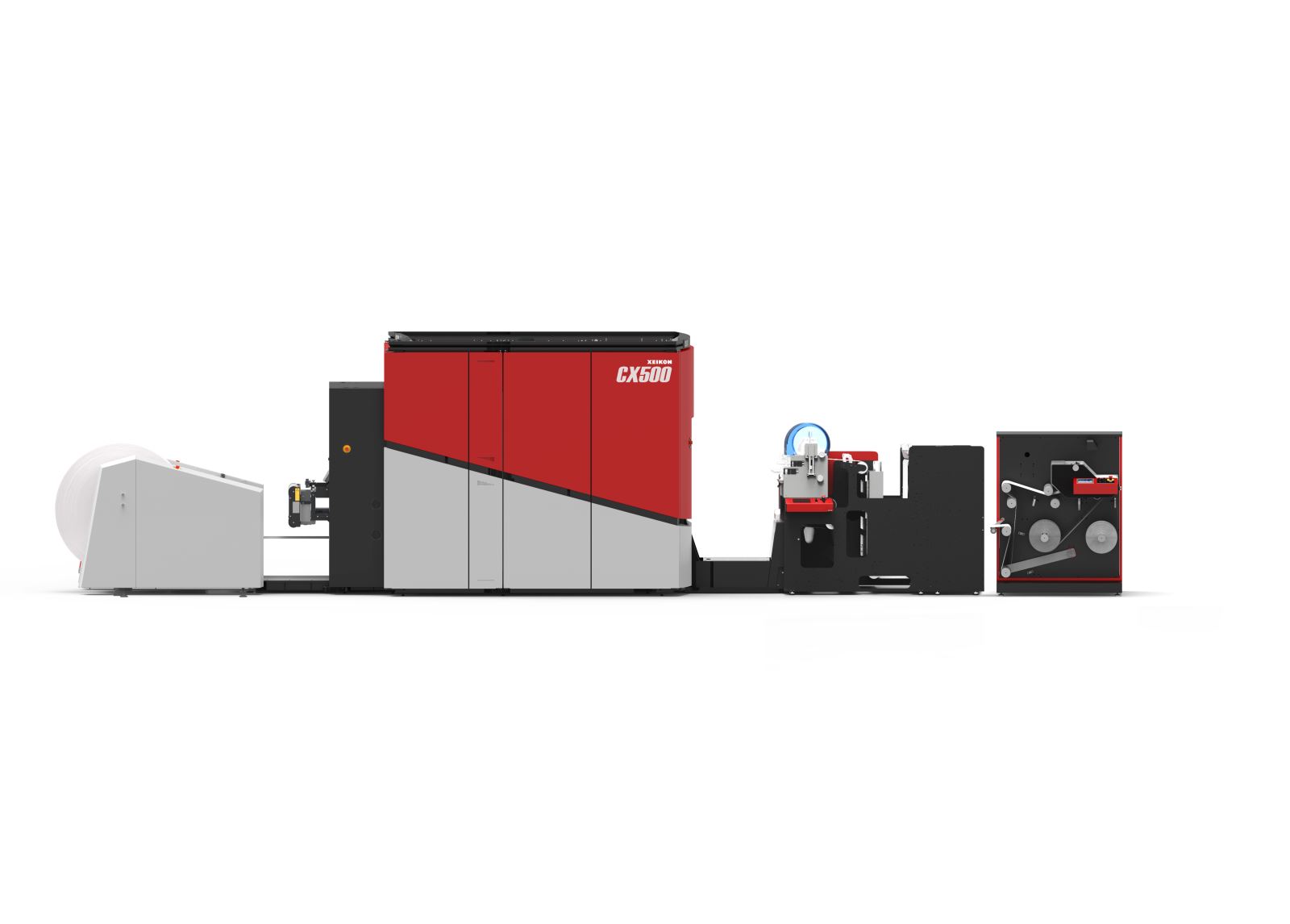

For example, a sample bag is printed on the Xeikon CX500 digital laminator .

- Chất nền: D&K ADB 1/2

- Toner: Cheetah toner CMYK + White, Coating Michelman Digiprime 4453

- Finishing : Xeikon Site Finishing Module , Xeikon Print Media Reworker

- The CX500 has become the press of choice because of its 516 mm (20.3") web width allowing for efficient solution creation.

3. Digital printing value

Printing technology brings a lot of value with many outstanding advantages:

- High print quality

- Intersection with flexo at least 4,000 linear meters

- No startup costs

- No cost of switching jobs on the same print media

- Ability to print unlimited quantity versions (SKUs) in one go

- The ability to print single and full color variable information, built into the bag

- Shared: